When the Dioxycle team entered the Breakthrough Energy Fellows program in 2021, they were a team of four people. Co-founded by David Wakerley and Sarah Lamaison, Dioxycle created the world’s first electrolyzer that eliminates fossil fuels from the production of ethylene—the world’s most used organic chemical. The current ethylene production process releases nearly 1 billion tons of carbon dioxide emissions annually.

Now, that team includes 25 scientists, engineers, and industry experts—and is rapidly growing. Dioxycle announced the closing of its 17 million dollar Series A funding round in July of 2023, becoming a Breakthrough Energy Ventures portfolio company alongside investments from Lowercarbon Capital and Gigascale Capital.

Where did Dioxycle’s journey to tackle CO₂ emissions begin?

The pair met in 2016 at the University of Cambridge where David was finishing work for a PhD and Sarah was finishing her Engineering degree from École Polytechnique. With a shared passion for new technologies and aversion to pollution, they dove deep into academic studies of carbon electrolysis, seeing it as the missing technological link to turn renewable electricity and carbon emissions into renewable chemicals and fuels. Over 4 years, the two researched at the Collège de France and Stanford University, after which they published high-impact articles, and Sarah received a PhD.

By the end of 2020, they felt the urge to work at a scale more impactful than a typical research lab could handle. They founded Dioxycle with the aim of making carbon electrolysis a commercially viable process. Sarah notes, “When we left academia to start Dioxycle, we didn’t have the answers on how we were going to turn carbon emission electrolysis into an industrial reality, but we had a very good understanding of the problems to solve—and in some cases that can be 80% of the work already!”

The Breakthrough Energy Fellows Program supported Dioxycle’s early development, accelerating their work toward commercialization. When they entered the program, they were just about to complete the first prototype that would be needed to begin every future industrial build. The Fellows program guided the company’s growth with hands-on support in building out the technology, team, and business model that would propel Dioxycle forward.

David and Sarah graduated from the Fellows program with a proof of concept and a team of 18 scientists, engineers, and industry experts. For David and Sarah, the transition from the Fellows program to Series A felt seamless, with the knowledge and relationships they developed in the program preparing them for their ambitious goal to abate over 800 million tons of CO₂ emissions each year.

Dioxycle’s groundbreaking electrolyzer technology

Dioxycle’s breakthrough is an electrolyzer that is able to convert industrial carbon emissions into cost-competitive, sustainable ethylene. Ethylene is traditionally made by ‘steam cracking’ gas and oil at extremely high temperatures and releases 1-2 tons of carbon dioxide for every ton of ethylene produced. With ethylene a $230 billion global market, this amounts to nearly 1 billion tons of carbon dioxide emissions every year.

Dioxycle’s emission-to-ethylene electrolyzer therefore represents a massive decarbonization opportunity that could allow society to sustainably manufacture a near endless list of everyday essentials - to name a few: detergents, synthetic fibers, automotive parts, pipes, fittings, flooring, roofing materials, protective films, bottles, containers and medical devices are all derived from ethylene, and it can even be made into jet fuel.

Here’s how Dioxycle’s process works:

- The input emissions may contain carbon dioxide, carbon monoxide, or a combination of the two. If the feedstock is carbon dioxide, it’s first converted into carbon monoxide in a chemical reaction.

- Then, Dioxycle’s electrolyzer introduces the carbon monoxide to an electrically charged catalyst. This catalyst energizes the molecules, enabling them to reform as ethylene—a more energy-rich molecule.

- A final block purifies the ethylene for it to be transformed into everyday products.

Dioxycle’s technology provides a route to turn carbon emissions into an asset rather than a pollutant, unlocking pathways to 100% sustainable fuels with no further accumulation of CO₂ in the atmosphere. The electrolyzer transforms industrial emissions into sustainable ethylene solely utilizing renewable electricity and water. It will provide a solution for the many industries across the globe that have unavoidable CO₂ emissions in their processes.

What’s next for Dioxycle?

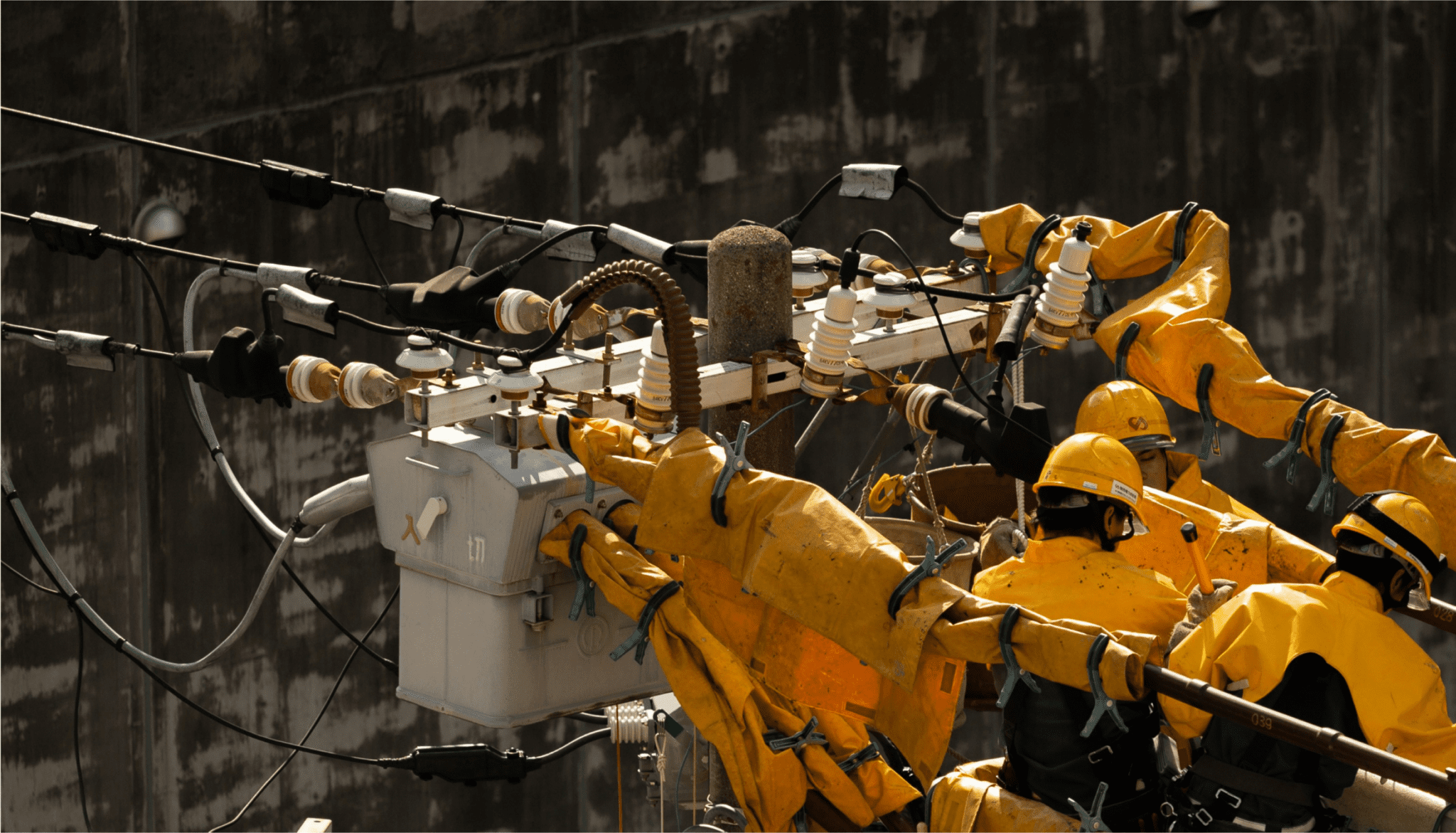

The Dioxycle team has new challenges to overcome as they progress into the next phase of their journey—building out an industrial prototype of the electrolyzer. David describes this as an, “Incredibly proud moment for Dioxycle, and a real testament to the unrelenting work of our fantastic team. Three years ago our technology was the size of a postage stamp, and now we have to lift it with a crane.” The Series A money will fund the build, followed by intense optimization. The Dioxycle team will continue to grow, recruiting senior experienced team members with a commercial interest in ethylene.

“Most chemicals are made through old-fashioned, emission-intensive processes, and their production grows year on year. Bringing this industry to net zero requires completely flipping it on its head: building chemicals up from carbon-based gasses rather than breaking down crude oil. This requires some hard work and creativity—and that’s what we are about at Dioxycle,” says Dr. Fanny Bétermier, Head of MEA Engineering.