Explore the Projects

The BE Fellows program supports innovations across all Five Grand Challenges.

Explore job openings in the BEF portfolio.

The BE Fellows program supports innovations across all Five Grand Challenges.

Explore job openings in the BEF portfolio.

Arinna

Arinna is empowering humans and machines with abundant solar energy via its paper-thin power-dense solar panel technology.

Barocal

Barocal is revolutionizing cooling and heating with a breakthrough solid-state technology that offers very high energy efficiency without harmful refrigerant gases.

Celluol

Celluol is using the power of biology to convert underutilized waste such as crop or forest residues into fuels and chemicals.

Clear Skies H2

Clear Skies Hydrogen (CSH2) seeks to deliver refueling with diesel-parity cost and operating convenience to unlock large-scale adoption of hydrogen for trucking and heavy-duty transport.

CRecTech

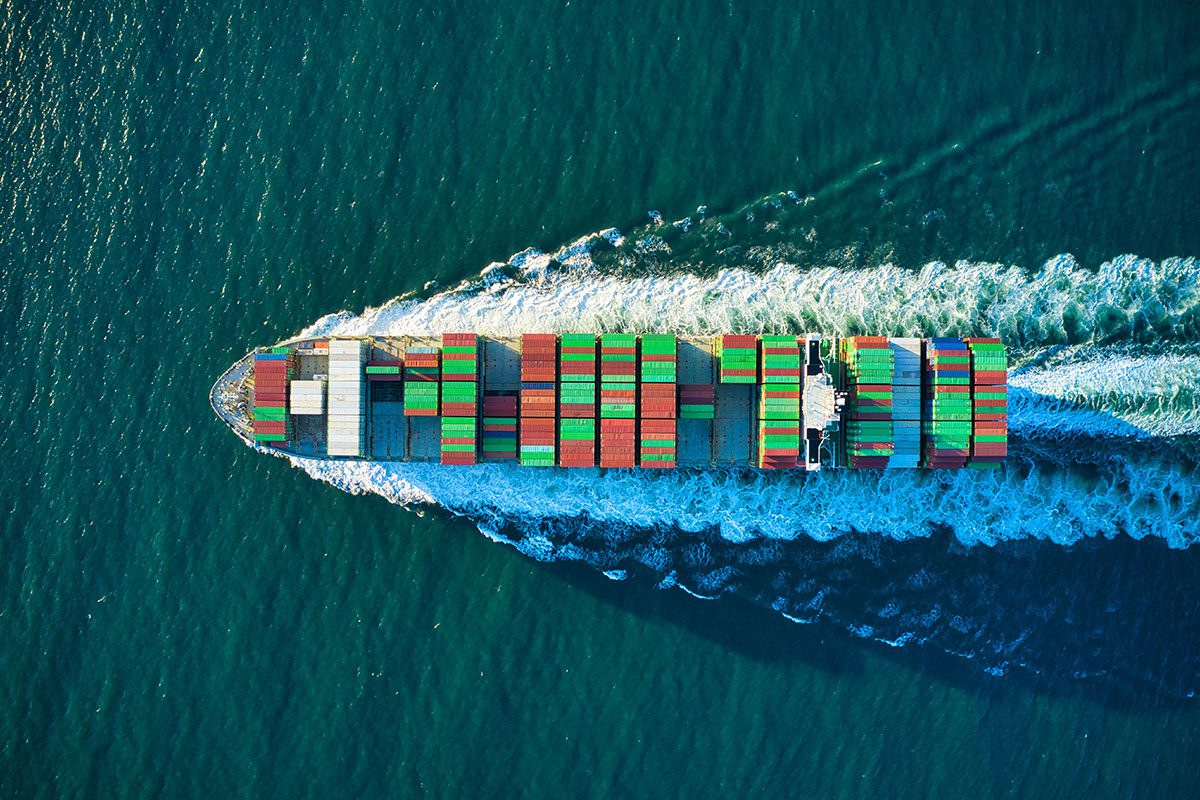

CRecTech has developed a novel catalytic technology that simplifies the operational process and production cost of converting biogas into bio-methanol, making renewable methanol fuel more affordable for the maritime sector to accelerate their transition toward net zero CO2 emissions.

Espiku

Espiku’s technology concentrates Li-containing brines while also producing clean water and solid salts; this enables cost-competitive mineral extraction with no fouling, no membranes, no liquid discharge, and minimal environmental impact.

Gallox Semiconductors

Gallox Semiconductors is reducing energy waste by improving the efficiency of power conversion through the use of gallium oxide-based transistors and diodes.

HyperHeat

HyperHeat is developing an all-electric industrial heater which can reach 2000°C to directly electrify industrial processes in hard-to-abate sectors such as steel, cement, chemicals, and glass.

Lincore

Lincore has developed a refining technology to extract critical materials from spent Li-ion batteries with a variety of chemistries and process them into ready-to-use battery precursors while minimising waste, creating circular battery supply chains.

Loamist

Loamist's platform simplifies the sourcing of renewable biomass feedstocks by combining software with a physical network to gather, standardize, and track biomass feedstocks.

Prospect Growth

Prospect Growth manufactures nanofertilizers that boost crop yields, decrease costly nutrient inputs, and minimize environmental losses.

Rarefied

Rarefied is developing a novel propulsion mechanism that allows lightweight platforms to stay aloft in near-space (30-100 km altitudes) using only sunlight.

Sinkco Labs

Sinkco Labs is developing a scalable and cost-effective solution for permanently storing organic carbon in marine sediments, ensuring safe and verifiable carbon removal

Standard Potential

Standard Potential is scaling sodium-ion battery technologies that use earth abundant minerals and optimize manufacturing for sustainable energy storage.

Step Function

Step Function is leveraging the chemical potential of ferrous iron rich natural minerals and industrial wastes to produce low-cost carbon-negative fuels.

Sustainable Chemicals

The world is drowning in plastic pollution. Plastic manufacturing currently accounts for a large and growing fraction of global CO2 emissions, while only a small percentage of plastic is ever recycled. Our aim is to achieve meaningful environmental change by designing a bioplastic that is cost and performance competitive with petroleum-based plastics.

Aikido Technologies

Aikido Technologies has designed a self-erecting platform for floating, offshore wind turbinesto overcome key barriers to increasing offshore wind energy production.

Aluminio

Developing a new approach to using aluminum to replace the silver used on solar cells, reducing the costs and accelerating adoption of more efficient cell designs.

Arculus Solutions

Arculus Solutions is future-proofing current natural gas transmission pipelines to safely transport hydrogen.

Aspiring Materials

Aspiring Materials is tackling industrial CO2 emissions from two angles - what goes in and what comes out. And we’re using commonly found rocks to do it.

Calion

Calion is reshaping the cooling and heating landscape by replacing harmful refrigerants with salt and water – the world’s two safest and most abundant materials.

CemVision AB

CemVision AB combines three different technologies into one process to reduce carbon emissions from cement and concrete production.

CERT Systems Inc.

CERT Systems Inc. has developed an electrochemical process that uses only water and electricity to convert captured carbon dioxide into basic chemicals that can be used to make everyday products including green chemicals, fuels, and plastics.

Chement

Chement’s patent-pending technology eliminates all CO2 emissions in cement production.

ChemFinity Technologies

Developing new porous membrane materials to reduce the energy needed to purify salt water and recover valuable metals.

ClimateCrop

ClimateCrop enhances plants' genetics using non-GM techniques to increase yield per unit area with less inputs, resulting in a lower carbon footprint.

Conduit Tech

Conduit Tech develops tools that make it easier for heating, ventilation, and air conditioning (HVAC) contractors to install and maintain low-emissions residential heating and cooling technologies.

Dioxycle

Dioxycle is a company that is converting carbon dioxide into valuable products through low-temperature electrolysis.

Electroflow Technologies

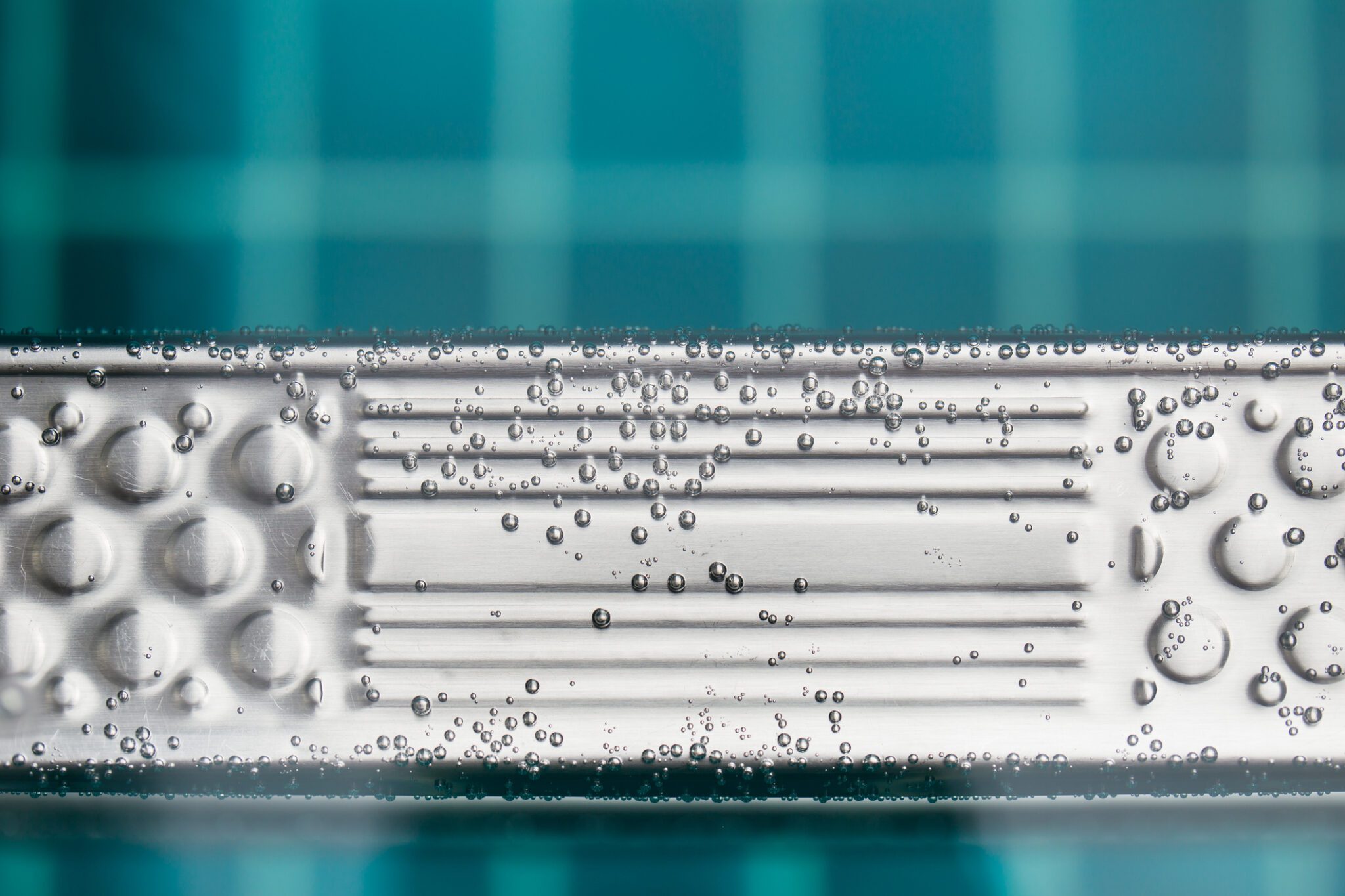

Electroflow Technologies is decarbonizing lithium production by using renewable electricity to convert saltwater into battery grade lithium chemicals.

EvolOH

EvolOH (ee VOH loh) is blazing a path toward low-cost, green hydrogen production using innovative electrolyzer materials and hardware.

Ferrum Technologies

Ferrum is leveraging their unique hydrogen-plasma technology to produce carbon-free steel.

Furno

Furno Materials is working to re-envision the way we make cement, leveraging oxyfuel combustion and a novel design to enable the production of zero-emission ordinary portland cement.

Gencores

Gencores produces high-performance, lightweight materials for light-duty automobiles, increasing vehicle efficiency and range.

Hertha

Hertha is developing an iron and steel manufacturing process that replaces coal with renewable power and hydrogen to reduce sector emissions by more than 95%.

Hgen

Enabling cheaper and more efficient clean hydrogen production that seamlessly integrates with renewable energy systems.

Holocene

Holocene is developing a direct air carbon capture system that utilizes organic chemical compounds to increase capture efficiencies and reduce energy consumption by lowering regeneration temperatures.

Hoofprint Biome

Hoofprint Biome is developing probiotics that improve cattle health and digestive efficiency while eliminating methane production.

Liquium

Liquium is revolutionizing the ammonia production process, making it cleaner, cheaper, and scalable enough to decarbonize heavy industries, including shipping, aviation, heat and power generation, and chemical production.

Litherm Technologies

Litherm Technologies GmbH is electrifying key processes in lime and cement production to eliminate fossil fuel-generated CO2 emissions—and capturing remaining emissions for storage.

MacroCycle Technologies

MacroCycle seeks to decarbonize the plastics industry by upcycling low quality waste plastics into high quality plastic products through a novel low-energy chemical process.

Mantel

Developing the first high-temperature liquid-phase carbon capture materials for use in industrial processes that could substantially reduce costs and energy losses relative to incumbent technologies.

Marathon Fusion

Marathon Fusion designs, engineers, and scales next-generation fuel-processing technologies to enable the deployment and scale-up of fusion power plants.

Mars Materials

Mars Materials is commercializing a technique that transforms captured CO2 emissions into a compound used to produce low-cost, low-carbon materials for industrial use.

MetPeel

MetPeel is a new manufacturing process for making steel sheet and strip using a unique low-temperature, single-step process in place of conventional fossil-fired hot rolling.

Molten Industries

Molten Industries is developing a process to create low-cost hydrogen that avoids carbon emissions while consuming seven times less renewable electricity.

NitroVolt

NitroVolt is decarbonizing nitrogen-based fertilizer production and making the agricultural sector more resilient with a novel production process.

Novel Farms

Novel Farms is developing a scaffolding platform designed to enable the cost-effective production of whole cuts of cultivated meat at large-scale, accelerating the widespread adoption of this sustainable source of animal protein.

Olokun Minerals

Olokun Minerals uses a mineral recovery process to provide mineral-based products sustainably sourced for a variety of industries.

Othersphere

Othersphere’s search engine for global infrastructure helps developers, financiers, and operators build better projects faster.

Phase Biolabs

Phase Biolabs leverages modified microorganisms to recycle carbon dioxide more efficiently into cost-competitive carbon-negative chemicals and carbon-neutral electrofuels.

Phycobloom

Phycobloom has developed modified algae that produces an oil that can be used for biofuels while also capturing carbon.

Queens Carbon

Developing a hydrothermal processing technology to significantly reduce the energy consumption and cost for both carbon capture and carbon-neutral cement production.

RenewCO2

RenewCO2 is commercializing a proprietary catalyst and one-step process to convert CO2 into cost-competitive carbon-negative monomers, chemicals, and fuels.

RIFT

Renewable Iron Fuel Technology (RIFT) is leveraging hydrogen and the rusting properties of iron to produce carbon-neutral energy for heat-intensive industries.

Silicate

Silicate permanently removes excess carbon dioxide from the atmosphere via the acceleration of a natural geochemical process – mineral weathering.

Takachar

Developing the first portable device for converting post-harvest crop and forest residues into bioproducts that can be used by even the most hard-to-access and underserved rural agricultural communities.

Unemit

Unemit’s direct air capture technology is scalable to gigatons, swift in its path there, and sustainable.

Verne

Verne is developing high-density hydrogen storage systems, minimizing the cost to transport and store hydrogen

In addition to Breakthrough Energy Fellowships, we offer 12-month, one-time grant awards for promising early-stage research.